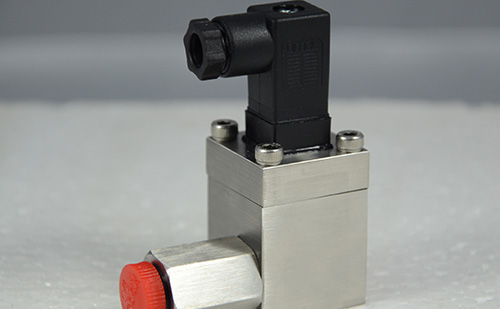

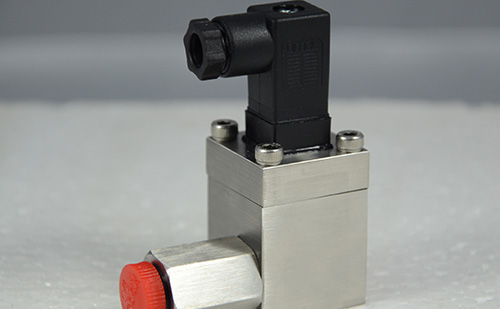

plasticizer mini flow measurement

email: porter@microflowmeter.com Shanghai JSN Micro Flow MeterCO.,LTD is a manufactory for Super MicroLiquid Flow Meter,Oval gear flow meter ,Mass Flow Meter,Circle Spur Gear FlowMeter,Gear Pump,Gear metering Pump etc. The company is a professional companyfor the production and supporting of automated instruments. It has strongtechnical force. The scientific research personnel account for more than 40% ofthe company"s total number of people. The production equipment is excellent andthe processing capability is strong. Since the new aviation instrument has anew and old research team, it not only produces the general-purpose flowmeasurement instrument in the market can also be designed and processedaccording to the user"s requirements in accordance with the user"s requirementsto solve the user"s various demands on the flow measurement.

plasticizer mini flow measurement

Onceupon a time, China"s manufacturing industry in the world"s processing plant hasalways been the "low quality" representative of the world. Inparticular, the Oval gear flow meter for automatic process control has theadvantages of large volume, large noise, small turndown ratio, , The use ofeasy to leak, instability and so on, leaving customers a headache is that manyproblems in the early stages of product does not appear, and in the event ofafter-sale is very troublesome, bothering money, these are domestic objectiveobjective existence of Oval gear flow meter Therefore, users buy Oval gear flowmeter is like buying lottery tickets, do not know sent to the installation siteOval gear flow meter is a blessing, in a sense, is a matter of course, whilethe base depth meter appeared to solve these problems in one fell swoop.

Oval gear flow meter, belonging to a type of volumetric flowmeter,cylindrical shape, with import and export, according to the media with a customfilter. Small size, light weight, easy installation, compact structure, withouttoo much maintenance; other The range ratio is very wide, generally more than1: 100, the minimum flow rate can be measured to 0.3ml / min; and thelinearization accuracy can reach 0.5% FS of full scale, so the use is very wideand can be used for measuring, regulating, controlling and distributing Highand low viscosity, or corrosive liquids, and there are health-type,explosion-proof for a special environment.

plasticizer mini flow measurement

The Ovalgear flow meter is a volumetric flow meter. The metering chamber is composed ofupper and lower end caps. The shell is formed by an oval gear rotor. The gearrotor meshes with the rotating shaft to convey the fluid. The permanent magnetarranged in the rotor is used for the detection of the rotor rotation. Twosensor holes are placed on the upper end to cover the detection sensor. Asealing ring is installed between the housing and the upper and lower end capsto prevent leakage of the measurement fluid. The base depth flowmeter is madeof a material with high wear resistance so that the flowmeter Can guaranteehigh precision measurement within the long service life.

plasticizer mini flow measurement

Technicaldata of CX-M Series micro oval Oval gear flow meter

Model | Flow range | Accuracy | Connection size |

CX-M2 | 0.5~150ml/min | 0.5% | G1/8" |

CX-M3 | 3~300ml/min | 0.5% | G1/8" |

CX-M5 | 5~1000ml/min | 0.5% | G1/8" |

CX-M6 | 0.5~100L/H | 0.5% | G1/4" |

CX-M9 | 6~600L/H | 0.5% | G1/4" |

CX-M12 | 0.3~30L/Min | 0.5% | G1/2" |

CX-M25 | 0.5~100L/Min | 0.5% | G1" |

What are the precautions for the gear flow meter?

1) When the flow exceeds the specified maximum flow rate, the Oval gear flow meter wear increases with the increase of the rotation speed, and the pressure loss increases sharply, should be avoided. Less than the minimum flow, although still able to measure, but the error increases. Flow meter The starting flow is about 2% of the maximum flow, and the normal working flow is preferably 70%-80% of the maximum flow.

2) Deep-rooted flowmeter is used with various viscosity media from 0.3 ~ 100000cps, different viscosity media will affect the range, the following single must be noted

3) The measured liquid temperature should not exceed the specified value, otherwise, the instrument can not work properly, or even stuck, the counter part is easily damaged at high temperatures. Liquid temperature changes will also cause additional errors in viscosity.